Solving common controls issues to save energy

Using a collaborative approach to energy efficiency, ecoDriver® Low Carbon Consultants identified & fixed building control issues which were responsible for significant energy waste

‘Heating costs rise by about 8% for every 1°C of overheating. Carbon Trust

Understand

It is never safe to assume that anything is working as expected; it is always better to check.

That is our mantra, and that is the basis on how we proceed in understanding how a client’s buildings are heated, cooled, ventilated, lit and controlled. First understand; then act; never assume and always check.

In this instance, we proceeded as follows:

- We consulted the hospital’s BMS expert for an overview of the HVAC controls

- We jointly investigated the HVAC weather compensation strategy

This was how we uncovered some common control programme issues, which when fixed will result in significant energy savings.

Working in collaboration with the hospital’s control system expert, we uncovered two simple errors, first by asking how the weather compensation controls were programmed.

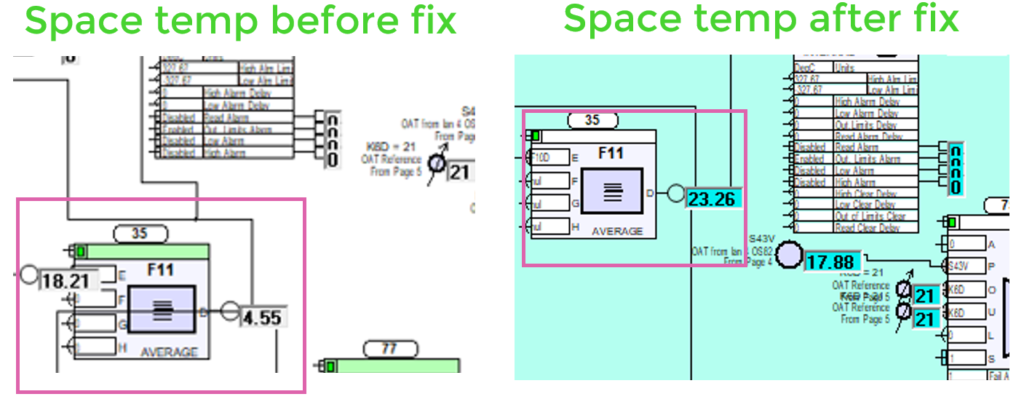

The variable temperature setpoint is calculated with reference to the Outside Air Temperature (OAT) compensation and space temperature. An average space temperature was configured to provide an output temperature which is the average (mean) of the four input temperatures. This is fine if the unused inputs are set to null but not so if the inputs are set to zero, as they had been. In this case the output was being computed as the mean of four values with three of these values always set to zero, hence the output was always much smaller than it should have been, by a factor of 4. Hence a low average space temperature was causing a much higher flow temperature, as the system thought is was much colder than it actually was. Hence energy was being wasted.

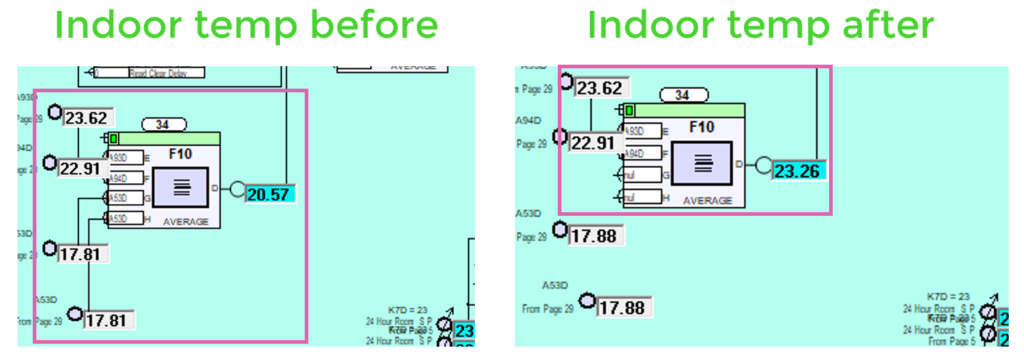

As we checked this aspect of the control strategy, we found another error where an OAT sensor had inadvertently been connected to another internal space temperature averaging module, so the internal temperature was incorrectly being adjusted based on OAT e.g. if the OAT was lower than the internal temperatures, the average would be lower as well. Again, this resulted in an understated internal temperature and thus a call for heat at times when none or little was required.

Act

In the two cases described above, the fix was applied to the control programme and the system now functions as expected

Background

Airedale General Hospital uses a CHP plant which generates heat and electricity for the hospitals use and it runs all year.

The CHP supplies heat to space heating circuits & DHW but if this is insufficient, it is supplemented by up to three gas fired boilers.

Reducing heat demand will reduce the occasions that these boilers are used, thus reducing cost and CO2e emissions and will help the NHS reach an 80% reduction by 2028-2032.

The issues found and fixed will contribute directly by reducing heat demand